ابزار Xhorse VVDI

Xhose VVDI نرم افزار برنامه نویس اصلی و سخت افزارابزار Xhorse VVDI

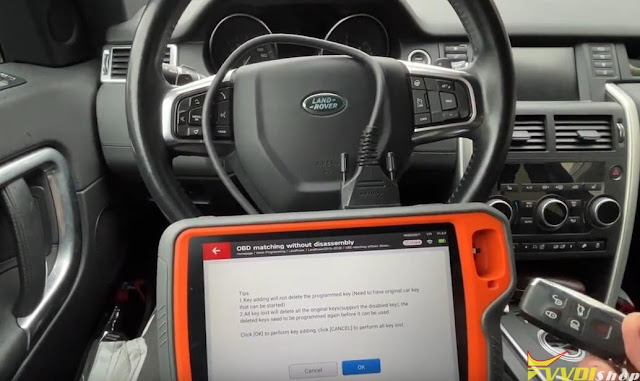

Xhose VVDI نرم افزار برنامه نویس اصلی و سخت افزارXhorse Key Tool Plus Program Discovery 3 2016 Smart Key

How-to: program Land Rover Discovery 2016 key (id49 chip) with xhorse vvdi key tool plus without removing the unit in 2 minutes. The procedure can be applied to other Land rover models from year 2015 to 2018.

Tool used:

Xhorse vvdi key tool plus tablet

Xhorse XS version smart key (here we use XSCS00EN proximity)

Original key

Procedure:

Go to Immo Programming->Land rover->Land rover (2015-2018)->OBD Matching without disassembly-> Smart key adding/All key lost

Add key will not delete the programmed key.

All keys lost will delete all original keys (Supports disabled keys). The deleted key need to be programmed again before it can be used.

Put an original key that can start the car into the vvdi key tool plus coil

Select the location with key ID to write start key.

The location without key ID cannot be used to write start key.

Insert xhorse XS smart key pcb into coil

Select an position with key ID to write key

Then follow keytool plus prompts to write key until finished.

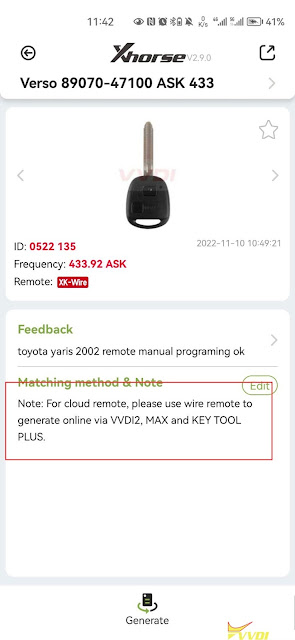

Can VVDI Mini Key Tool Generate Cloud Remote?

Question:

Can i use xhorse vvdi mini key tool to generate Cloud remote (remotes that are marked Cloud in the list)?

Answer:

No, mini key tool cannot generate Cloud remote.

Cloud remote has larger database, it can be generated by key tool max, key tool max pro, vvdi2 and key tool plus.

Which type of remote is to be used to generate Cloud remote?

You will need wire remotes (except B5 style) to generate Cloud remote.

VVDI Key Tool Plus Add 2005 BMW E90 320D CAS2 Key

How to use Xhorse VVDI Key Tool Plus to add a key for 2005 BMW E90 320D CAS2 by OBD? Following the steps below to learn.

Plug connector into OBD2 port,

IMMO Programming >> Europe >> BMW >> Automatically diagnose models >> Start programming

The current system type is detected as CAS2,

About to enter the system operation interface, please …

Read key information >> Yes

Insert the ignition key into ignition switch and connect the vehicle and device well.

Press “Yes” to continue.

The dealer key should be taken away from ignition switch.

If key is keyless, please move it out of car.

If there’s no key in ignition, continue anyway.

Press “OK”.

Save data file.

Prepare dealer key with programmer >> Select a blank key position: Key4

Please put new key into VVDI Key Tool Plus programmer.

Is the current key the smart key? No

Key make okay and locked. Please use it start the car.

If cannot start engine, use “Add key” function add the dealer key to CAS system.

If key can start engine, but keyless not working, please use “Repair keyless key” function.

Test the new key. It can start the engine normally.

Done.

How to Update MB Smart Key by VVDI MB Tool?

If you have a problem with Xhorse MB Smart keys. Cars would not recognize them, and sometimes they don’t run engine after programming.

On VVD MB click other functions, then Update MB Smart key

Set key frequency/upgrade smart key

1. Support specific manufacturer keys to change the key frequency through IR

2. Support the smart key of a specific manufacturer to upgrade to the latest version of the server through IR

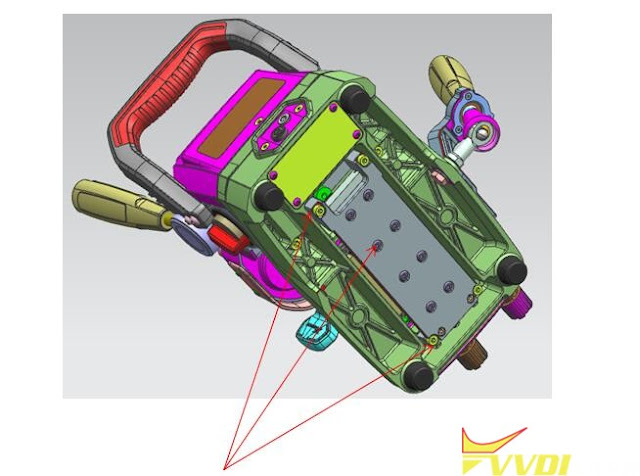

Xhorse Dolphin XP007 Workbench Shakes Solution

Problem:

My xhorse dolphin xp007 manual key cutting machine workbench shakes and two handles loosen. It will not cut key properly. How to fix it?

Solution:

First of all, follow solution here

http://blog.vvdishop.com/xhorse-dolphin-xp007-cannot-slide-back-and-forth-solution/

If problem still exists, follow instruction below:

I. Workbench shakes

Step 1: Check if the screws are loosened.

If yes, tighten it immediately.

Step 2: Check the gap between 1 (thin-walled bearing) and 2 (shaft).

If the gap is large, the shaft needs to be replaced.

Step 3: Check the limit of 2 axes. Move the workbench to the extreme left to discover this location.

If it is loose, please tighten the 2 limit screws to withstand the limit end of the shaft.

II. Workbench cannot move forward and backward

Step 1: Disassemble the dolphin xp-007 machine

Step 2: Check the cross slide and linear guide

Check the sides of the cross slide for scratches and bite marks.If yes, please use a file to smooth the scratches and bite marks.

Check whether the sliding of the guide rail is stuck.

If there is stagnation, please remove the foreign matter in the gap on both sides of the guide rail, and add guide rail oil.

Still can’t slide after foreign matter is removed. It means that the internal bearing of the guide rail is stuck, and there is a quality problem with the guide rail. Next, proceed to the third step.

Tip: In general, the second step can solve the problem that the workbench cannot move forward and backward.

Step 3: Disassemble the linear guide for repair

Loosen 8 screws

Push the guide rail, push the end face A of the guide rail to the position of the red line, and push the end face B of the guide rail to the position of the yellow line.

If it can be pushed, the foreign matter can be discharged by filling the guide rail with oil until the guide rail slides smoothly.

If the guide rail still cannot be pushed, please restore the device and return it to the factory for repair.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)