ابزار Xhorse VVDI

Xhose VVDI نرم افزار برنامه نویس اصلی و سخت افزارابزار Xhorse VVDI

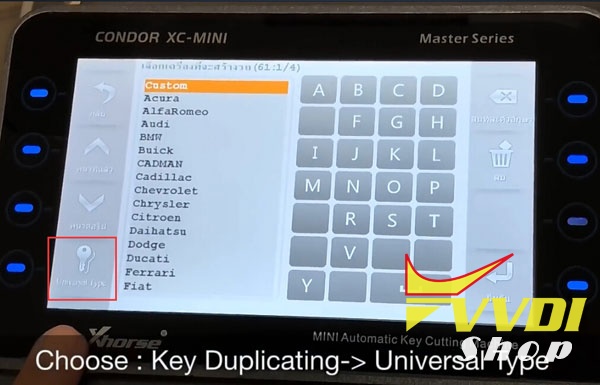

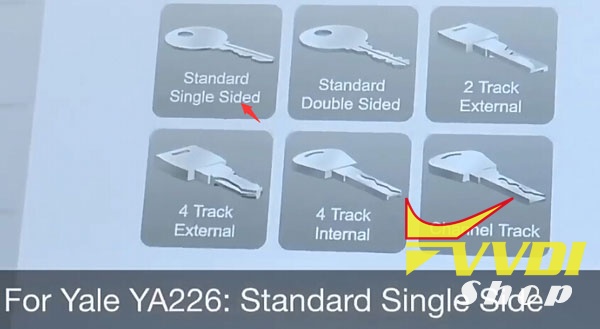

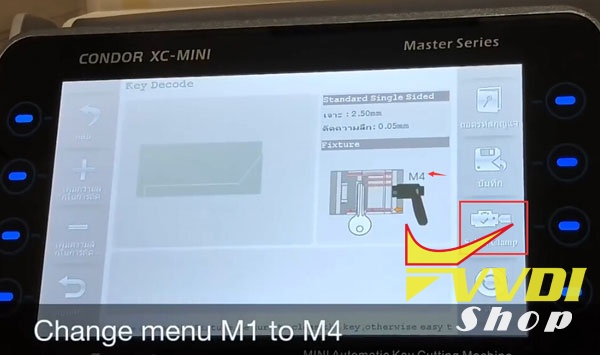

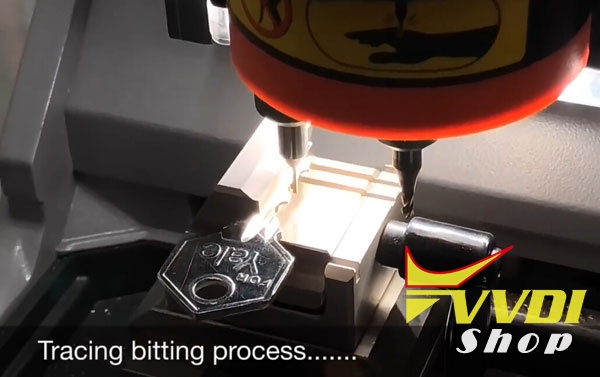

Xhose VVDI نرم افزار برنامه نویس اصلی و سخت افزارCondor XC-mini and M4 Clamp cut YA226 House Key

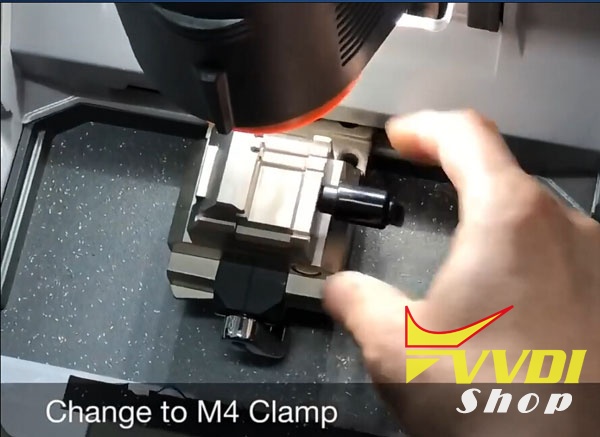

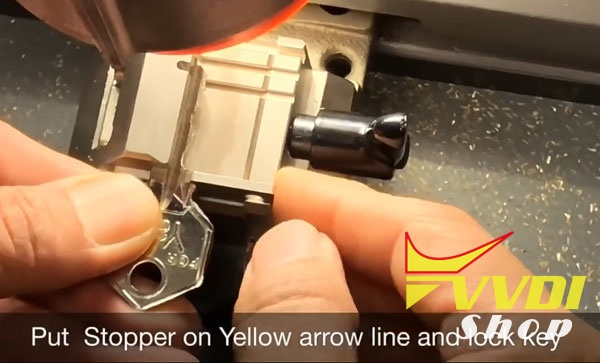

2.Recommended to use M1, M4 clamp and 1.5mm drill(cutter). Here we use M4 clamp.

How to change Battery of Condor XC-mini

This is the Power Supply Adapter with Battery for Xhorse Condor XC-Mini key cutting machine. No need to connect Car inverter, battery as power supply, easy to carry out. Support household electricity and cigarette lighter to recharge or use as power supply.List of rechargeable battery of XC-Mini

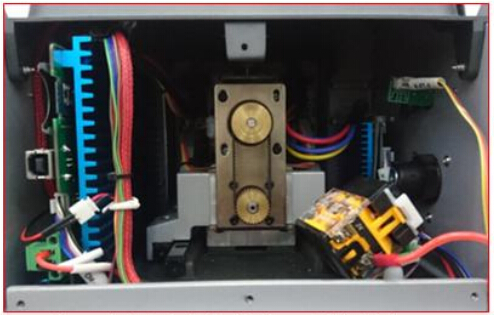

① Mainboard

Specification of rechargeable battery of XC-Mini:

Note: The update version Condor XC-Mini Plus with built-in battery is coming soon. Don't need to change chargeable battery any more.

Xhorse Condor XC-Dolphin vs. Condor XC-Mini

It is a small, compact machine with 10kg of weight.

And of course as everything new these days – it is controlled by connecting to your phone by Bluetooth. Possible to connect to computer too.

| index | XC-DOLPHIN | Condor XC-MINI |

| Spindle | Mechanical shaft +60W DC motor (with a foreign model)” “Electric spindle brushless 300W, built-in angular contact bearing | Electric spindle brushless 300, built-in angular contact bearing |

| Transmission mechanism | “T-shaped screw + anti-backlash nut | Ball screw |

| guide | Roller guide | Cross-track |

| shell | Base aluminum alloy die-casting, the upper body is made of plastic shell and the body is made of integrated aluminum alloy die-casting. | Plastic outer casing body is formed by body alloying die casting |

| Fixture | Standard fixture | Two sets of standard fixtures |

| Manipulation | No touch screen, no built-in database | Quick start, with touch screen, built-in database |

| Offline operation | not support | stand by |

| Dedicated app | Support dedicated mobile phone APp | Support dedicated mobile APP |

| Built-in battery | Not supported, optional external battery | stand by |

| protecting mask | Simple protective cover | Comprehensive protection |

| VVD binding | not support | stand by |

| Cutting speed | 1X SPEED | 2X SPEED |

| weight | <10kg | 18kg |

| Warranty | 1 year | 3 years |

Xhorse Condor XC-Mini Software Update to V5.0.9

Xhorse Condor XC-Mini (KM03) key cutting machine software released to V5.0.9 (2018/05/23).

Condor Mini 5.0.9 Update Feature:

Add universal key decode function

Add M2-D function

Add motor sensor testing function

Modify probe cutter detection

Fix machine may cra sh error problem

Fix HU49 key decide error

Fix HU66 cutting speed issue

Use the xhorse update kit to update Condor software:

https://mega.nz/#!QTx3yYKb!OW3Mc4sBaMqUSCUfWtPM4__Od-OPkemRe2j4EfPHRLo

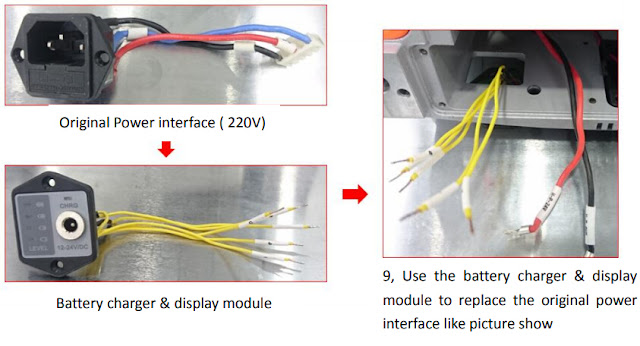

How to update Xhorse Condor XC-mini power supply

Xhorse released new power supply adapter with battery for Condor XC-Mini key cutting machine with which you can cut 40 keys per charge.

How to change/update Condor XC-Mini built-in power supply?

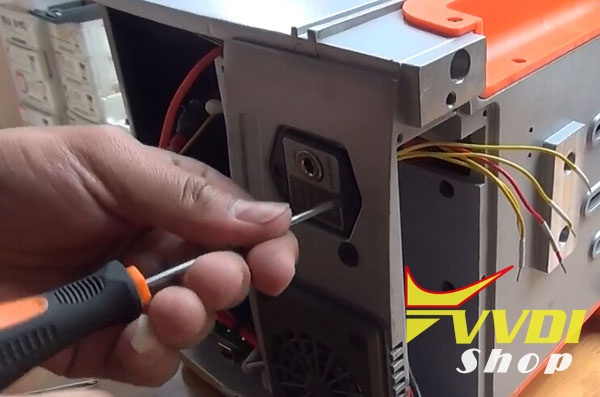

1.Remove the screws.

2.Remove the shell.

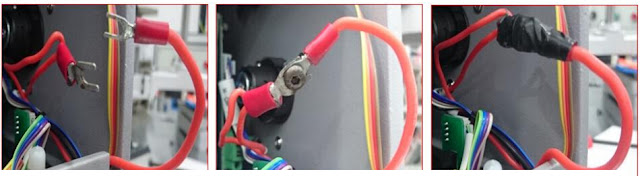

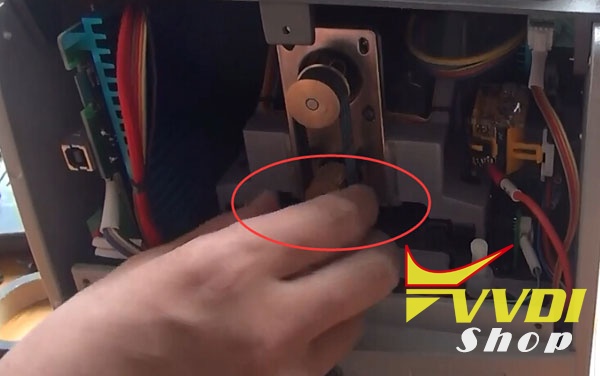

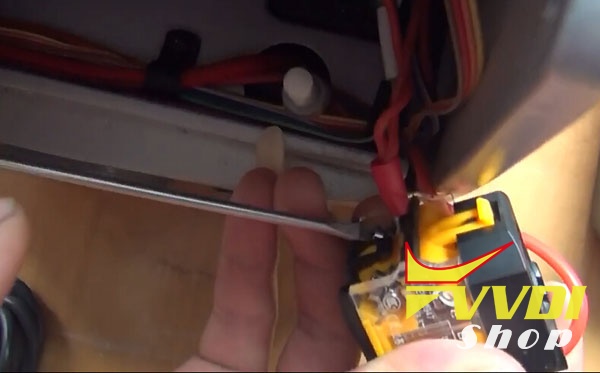

3.Rotate the little round screw to the innermost.

4.Then we need to remove the clip.Pull it out.

5.Rotate the screws on both sides,remove out the clip.

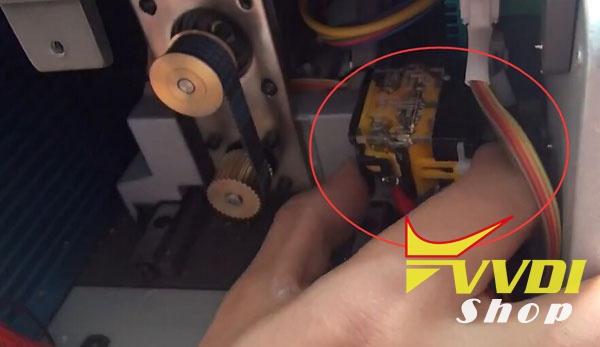

6.Use insulating tape to connect two cables together.

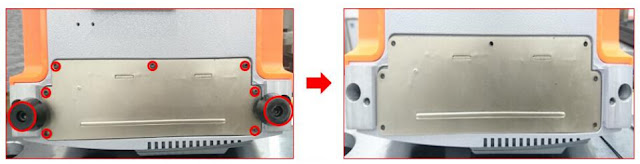

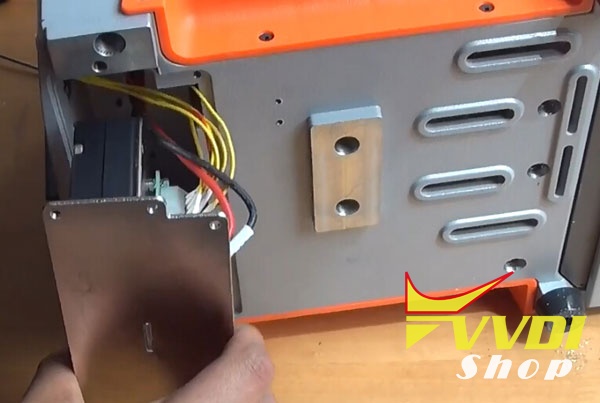

7.Lay down condor mini machine.Remove the screws.

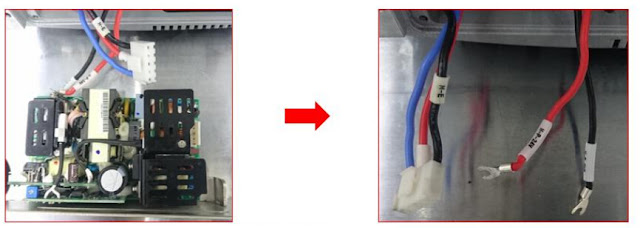

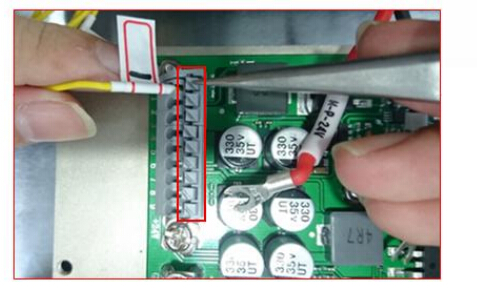

8.Take out the board.Unplug the clip.

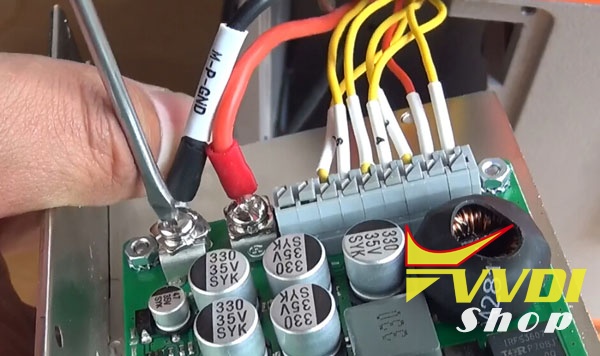

Rotate two screws to remove the cables from the PCB.

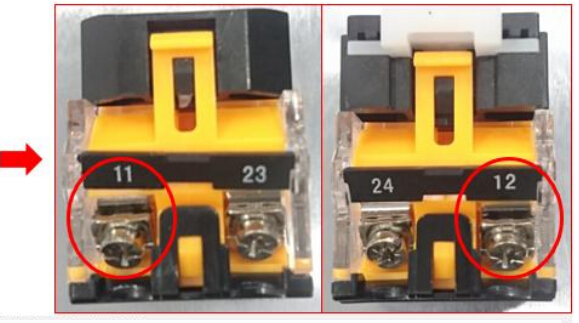

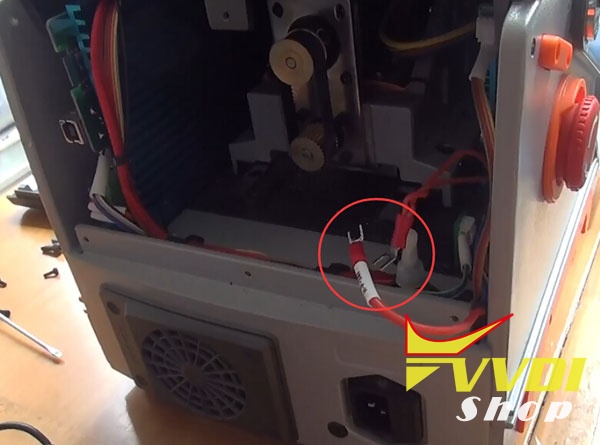

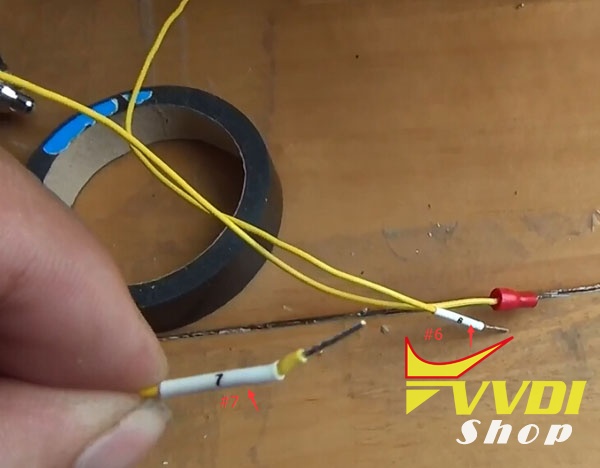

9.Here two separate yellow color cable,number 7 and 6.

10.Number 6 cable is connected to 12 on clip.

Cable 7 connects with 11. Lock the screws.

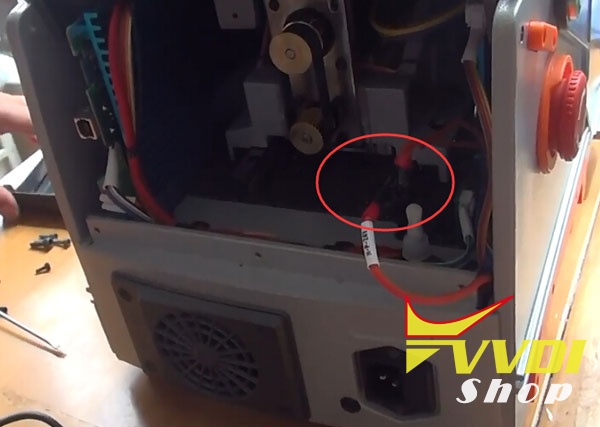

11.Put back clip to original place.

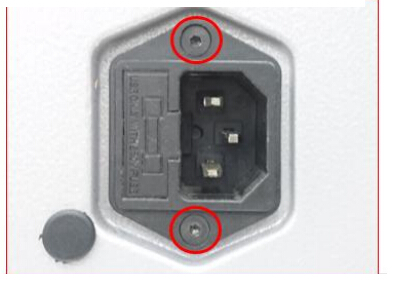

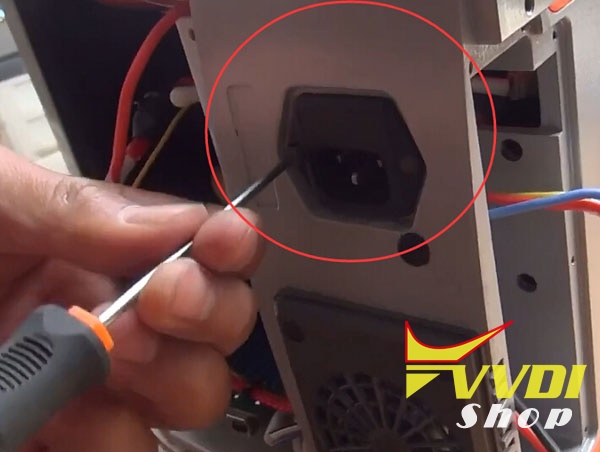

12.Next step: remove the power adapter on Condor MINI

13.Put the new power adapter.You can find new power adapter in Power Supply Adapter with Battery Kit.

Put back screws and lock it.

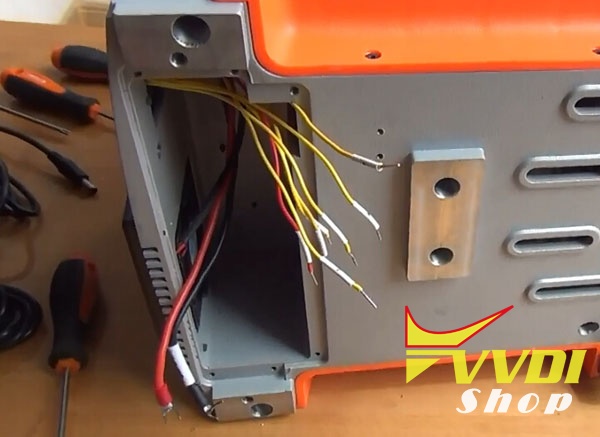

14.Put two yellow cables together with new power adapter cables under the clip through the hole.

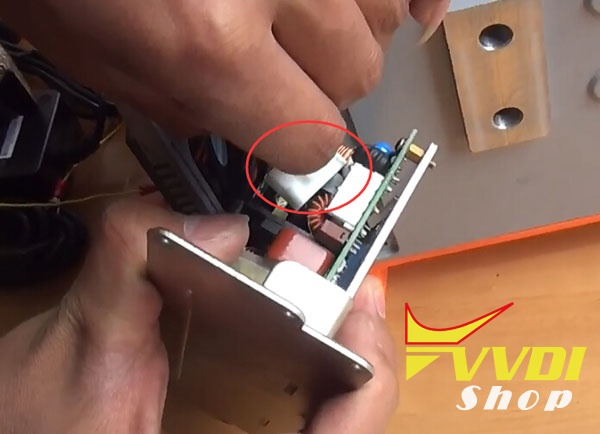

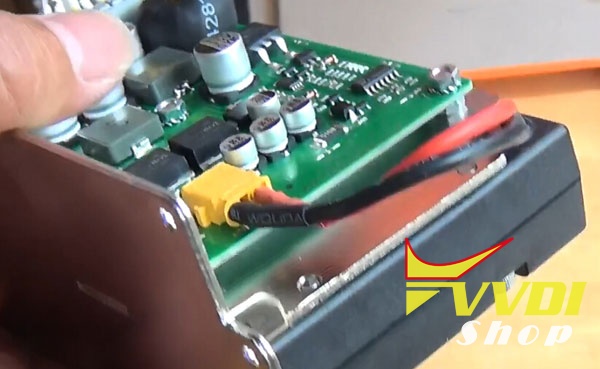

15.Connect Power Adapter battery PCB.

It lists out number from 1 to 9,and 24V.

16.Connect cables to the numbers, VCC and GND. Please note the numbers must be matched.

Connect cables,as well as VCC and GND.

17.Put back PCB to condor mini.And two shells,lock the screws.

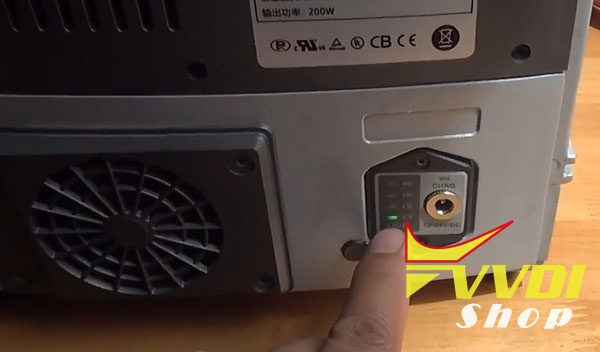

18.Now,we power on to start for test.It shows charge capacity.

19.Use old charge cable with new charge adapter,connect with power supply,it can charge power.

We can also use Car cigarette lighter cable to charge.

20.Upgrade to the built-in power supply successfully.